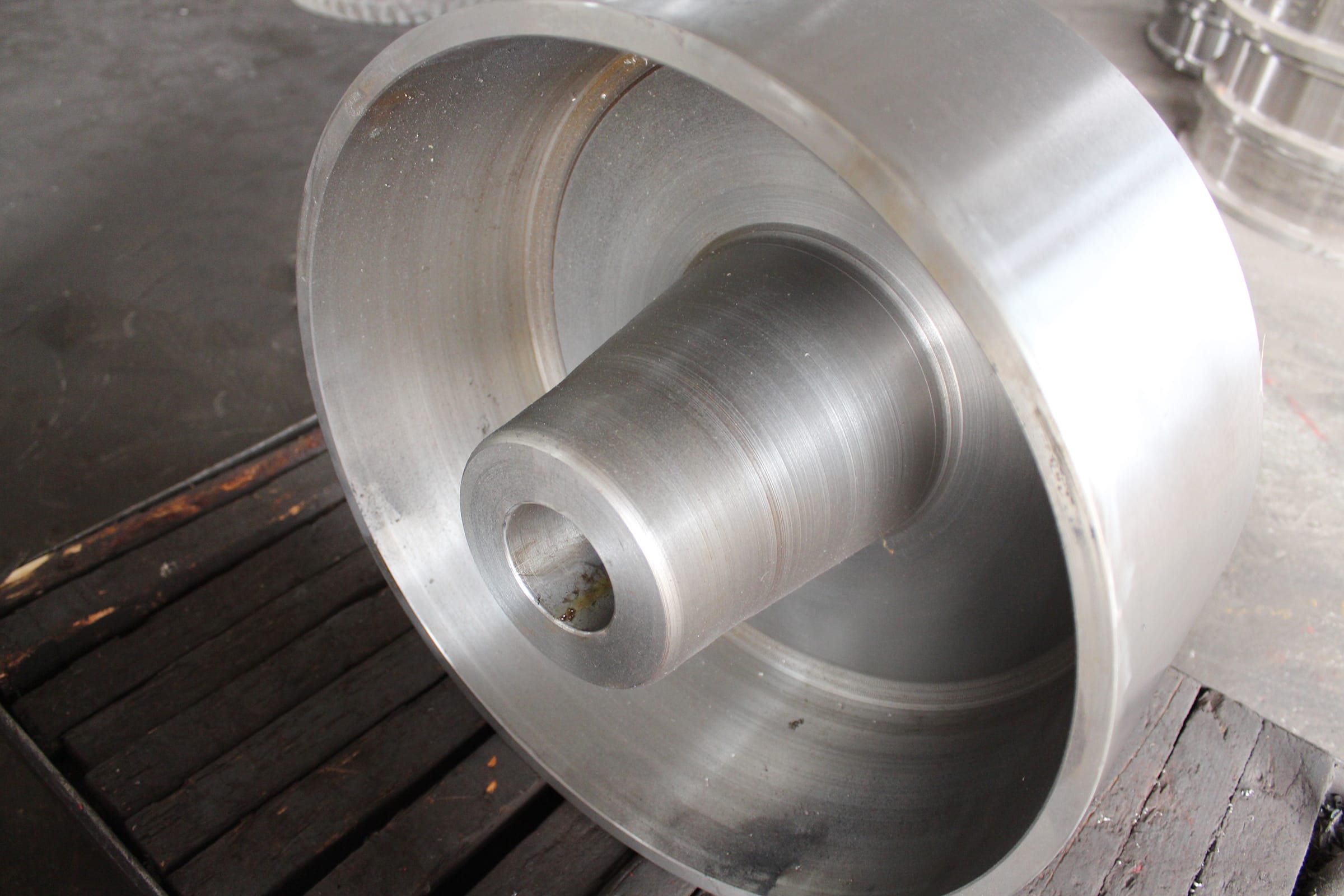

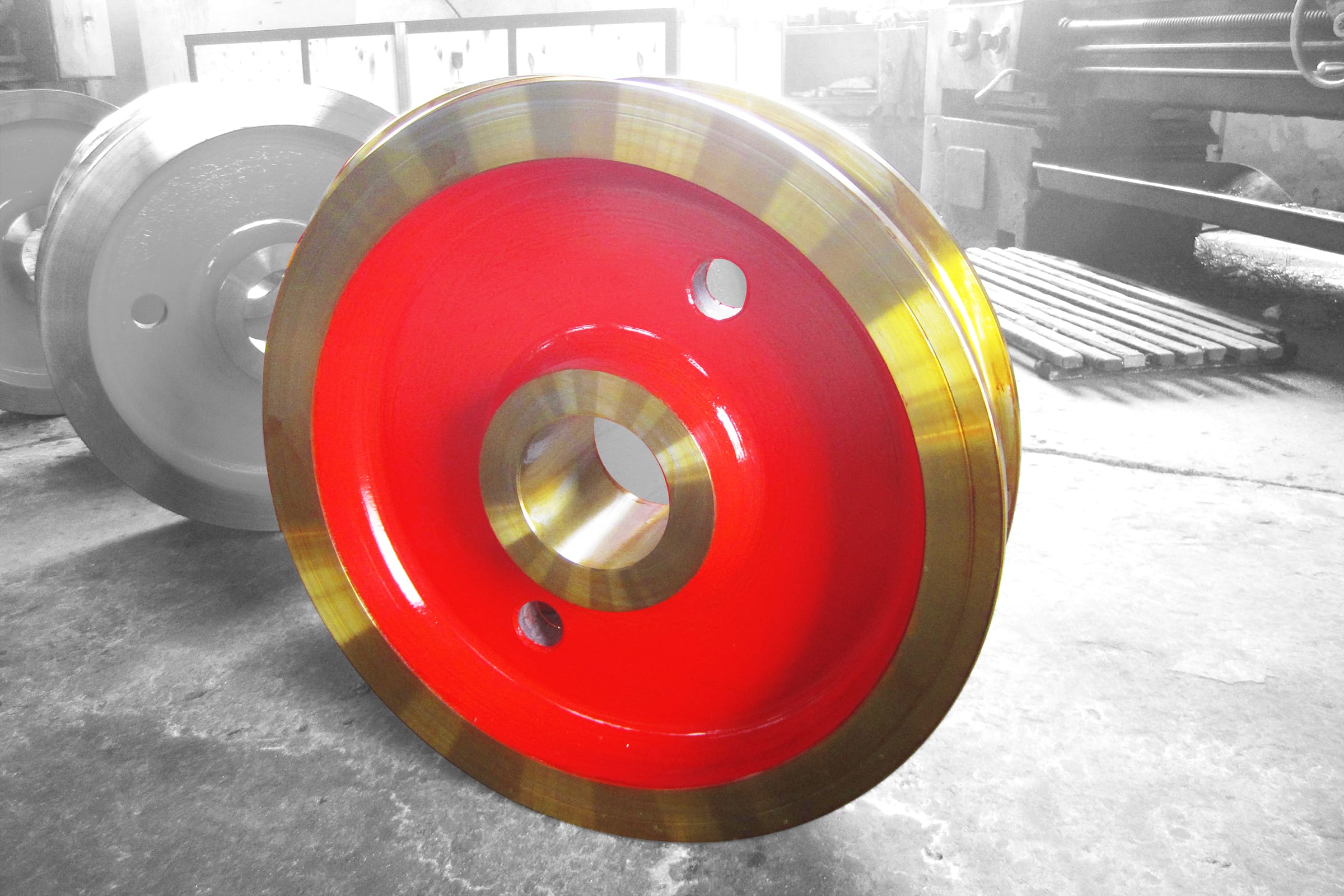

Fabriquées à partir de matériaux durables comme le ZG340-640, le 65Mn et le 42CrMo, les roues de grue XDREAMTECH subissent un traitement thermique avancé pour une durabilité exceptionnelle. Leur diamètre (Φ160–1000 mm) et leur largeur de voie sont personnalisables, et leurs bandes de roulement trempées (HB330-380) offrent une résistance supérieure à l'usure.

Caractéristiques du produit

- Plage de diamètres : Φ160–1000 mm

- Options de matériaux : acier forgé ZG340-640, 65Mn, 42CrMo, 60#

- Personnalisation : les matériaux, les diamètres et les largeurs d'installation peuvent être personnalisés pour répondre à des exigences spécifiques.

Options de matériaux

- ZG340-640 : Acier moulé à haute résistance avec une résistance à l'usure exceptionnelle.

- 65Mn : Acier au manganèse optimisé pour une absorption des chocs et une ténacité supérieures.

- 42CrMo : Acier allié au chrome-molybdène offrant une résistance élevée à la fatigue et une stabilité thermique.

- Acier forgé 60# : Acier forgé de précision, garantissant une durabilité inégalée et une capacité de charge élevée.

- Personnalisation : Des matériaux, des diamètres et des largeurs de voie personnalisés sont disponibles pour répondre à des exigences spécifiques.

Principaux avantages :

- Durée de vie prolongée : les surfaces de bande de roulement durcies réduisent l'usure jusqu'à 40%, ce qui les rend idéales pour les environnements à friction élevée.

- Capacité de charge élevée : les matériaux renforcés et le traitement thermique permettent aux roues de résister à des pressions extrêmes et à des charges dynamiques.

- Ajustement personnalisé : conçu pour s'adapter à différents types de rails (largeurs de rail standard ou personnalisées) pour une compatibilité transparente.

- Faible entretien : l'ingénierie de précision minimise la déformation et la fatigue de la surface, réduisant ainsi les temps d'arrêt.

Scénarios d'application :

- Grues : Ponts roulants monopoutres, ponts roulants bipoutres, ponts roulants à portique et ponts roulants de fonderie.

- Transport électrique : wagons plats électriques, chariots de transfert sur rail et bogies pour aciéries ou usines automobiles.

- Manutention : déchargeurs de navires, manutentionnaires de conteneurs, gerbeurs-récupérateurs et manutentionnaires de matériaux en vrac.